Effective safety communication is important for all organizations, but in the manufacturing sector it’s vital. Injuries in these environments can be much more severe than in other contexts, like at a corporate hub, plus stock and equipment can get damaged. This can also be costly in a monetary sense; when factoring in things like lost time and cleanup in addition to direct costs, the financial cost to an organization is often estimated at around $10,000 (though it can go a lot higher). And that doesn’t include the increase in insurance premiums, OSHA penalties, and the like.

But at its heart, workplace safety is really about the people. When a coworker gets injured, morale goes down and people become less focused. And if workers think management doesn’t care, they can disengage, which could cause yet more accidents. Too many accidents, and the organization’s productivity, quality and reputation start to suffer as well. And then people might start thinking about finding somewhere else to work, and the costs associated with finding and onboarding new workers are known to be high, especially for workers with special skills.

So, it’s in everyone’s best interest that accidents happen as seldom as possible, and that employees down on the factory floor, in the warehouse, or wherever, know and believe that management is actively watching out for them. Enter employee health and safety communications.

Draw on OSHA Resources

Communicating OSHA standards is one of the cornerstones of effective safety management. They have a broad view, but also drill down to quite specific safety standards for a number of things, ranging from ladder or scaffolding inspection to tool safety and first aid. OSHA can even supply you with ready-made materials, such as safety posters and brochures for break rooms. And, of course, you are also legally required to comply with their guidelines.

A larger organization will probably have some materials from headquarters they can use as well. You want your reminders and messages to be relevant to the specific environment workers are operating in. No sense talking about chemical storage on a construction site (unless, of course, you have chemicals on site). But more general reminders about both physical and mental health can also contribute to a solid Environmental Health & Safety (EHS) culture.

Even a smaller independent operation has access to plenty of materials to help shore up their internal safety communications. Local trade organizations and even unions might have materials you can use to bolster EHS communications.

Digital Signage for Safety Messaging

Many of the things you get from outside sources will be physical – signs, safety posters, etc. Putting them around the facility or work site is certainly a good idea, but you’ll have to refresh them regularly, and it can be hard to draw attention to a poster that’s been on a bulletin board for weeks. This also limits you to more general safety notices instead of communications tailored to your workforce.

Instead, consider using digital signage to get EHS messages out and reinforce your safety culture. Digital signage is dynamic – visual, bright and animated messages that change every 7-10 seconds. And in noisy plants where workers move around a lot, visuals on screens placed throughout a facility can change regularly to spark attention. A lot of what you want to communicate is more reminders than new information, and a constantly changing playlist of digital messages can make even the same tired old info seem fresh and new.

You can do a quick redesign of content that needs to be repeated – move the text from the left side to the right, change the image that reinforces what the text says, alter the colors, etc. Suddenly, it feels like a brand-new message, and your audience will react as if it is. This is one of the reasons why digital signage has been proven to greatly increase engagement in any communications context, but especially for internal safety communications where the information remains important, even though it’s being repeated.

You can take those OSHA materials, for example, and quickly turn them into a series of dynamic text slides, images or videos. A single OSHA list of requirements can be turned into a dozen or so compelling messages, and the communications will have more impact because they’re more focused and targeted, instead of pages of text or long lists. To reduce the burden on your safety manager and content creators, create a few fill-in templates so creating and scheduling a message takes only minutes.

In addition to safety messaging, you can use digital signs to publish weather and news, general announcements, HR info and realtime data. Production stats, inventory tracking, shift schedules and other data sources can feed directly into the digital signage system to automatically create messages that reflect updated on-the-ground data. Tying in something like an Excel spreadsheet means that as information is updated there, it’s also updated in your onscreen messages – no extra work required.

If you’re familiar with DOWNTIME, the eight deadly wastes identified in Lean manufacturing, you can read how digital signage can help with each of these in our previous blog.

SAFETY MESSAGES SUBSCRIPTION

Get a new visual every weekday to keep your staff motivated and healthy. You also have access to over 200 free message designs covering a range of topics from holidays and inspirational quotes to trivia and stress relief tips.

Motivation & Inclusion

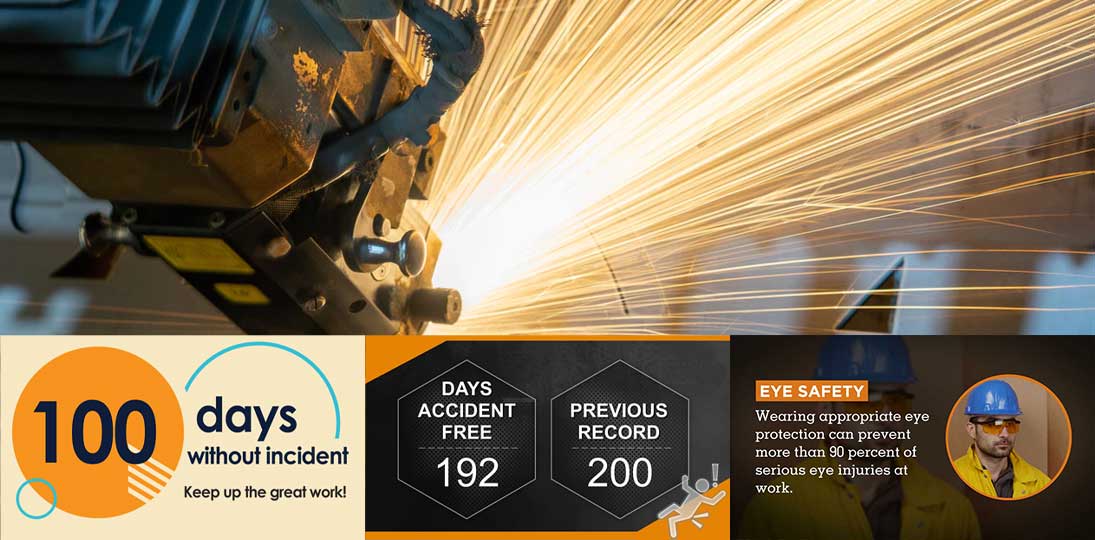

Employee safety communications are important, but so are other things. Tell people what they’re doing well, recognize achievements, motivate collaboration and inclusiveness, and bolster your corporate culture in addition to your safety culture. How many days has the production line been accident free? Have any employees or departments exceeded quota? If people are storing materials correctly, an EHS manager could take a quick picture and put it up on the digital signs with a “Good job!” message and a date and time stamp. This helps foster a positive atmosphere and can actually encourage people to be more diligent in the hopes that their good work will also be recognized on screens.

Digital signs aren’t just for safety committees and plant managers. Training can be reinforced as well. Again, short videos on screens in break rooms or other areas where people are spending time are great for reinforcing key elements of a recent safety seminar. Interactive touchscreens, even small tablet devices placed around the facility, greatly expand the possibilities, letting you offer on-the-spot refreshers or even quick quizzes to make sure everyone knows the new procedures.

And safety management at your location, whether it’s a warehouse or a fabrication shop or even an electrical utility, may want to come up with safety standards and improvements all their own. These don’t have to just come down from “on high” – let everyone be a part of the conversation. If you can’t offer touchscreens, solicit suggestions using QR codes or short URLs that people can access immediately with their smartphone, taking them to a dedicated webpage where they can suggest changes and improvements, and anonymously report deficiencies or violations.

And while work safety is certainly a serious issue, your messaging doesn’t have to be all instructions and requirements. A little humor goes a long way when crafting your content, or at least a lighthearted touch when possible. Inspirational messages have also been found to boost morale and productivity.

And don’t forget about your other employees! Office staff, HR managers and everyone else at the company need to follow procedures, and also need to feel motivated and appreciated. For them, add separate playlists in the back office, with reminders of upcoming deadlines and real-time data, so they can easily follow along with what’s happening in the company operationally.

You don’t create a safe work environment accidentally. It requires a dedicated team to create engaging, relevant content that’s informative while still being concise. Everyone needs to be in the same mindset, working from the same information to achieve the same goals.

Safety Communication Examples

When talking about the manufacturing sector, it’s probably a factory floor or a warehouse that comes to mind. While there’s certainly some crossover, both of these examples need different types of safety reminders and messaging. The same goes for other types of industrial facilities, such as transportation or utility companies. (If you’re looking for more general safety messages, you can get simple subscriptions to save yourself some time.)

Here’s a quick roundup of safety message topics that would be appropriate for each of these sub-sectors:

Manufacturing and Industry

- Machine guards

- General electrical safety

- Preventing falls, slips, etc.

- Clean up tips

- Potential hazards and obstacles

- Chemical storage

- Lockouts and tagouts

- Food handling

- Stress reduction

- Teamwork and morale

- Health and wellness

Warehouses

- Preventing slips and falls

- Preventing strains

- Preventing stains and spillage

- Balanced loads

- Forklift safety

- Aisle safety

- Pallet safety

- Dock safety

- Order accuracy

- Freight damage

- Shrinkage

- How to wear PPE (personal protective equipment)

- Protective eyewear

- Hardhats and helmets

- Ear protection

- Safety shoes and gloves

- How to store PPE

- Morale and teamwork

- Health and wellness

Transportation

- Driving safety (seatbelts, cell phones, etc.)

- Safe backing

- Vehicle inspection

- Proper lifting to prevent strains

- Driver turnover

- Three points of contact

- Balanced loads

- Customer service

- Morale and teamwork

- Stress management

- Conflict resolution

- Health and wellness

Utilities

- Special PPE

- Equipment safety

- Delivery system safety

- Insulation and isolation

- Safe work zones

- Public safety

- Proper lifting to prevent strains

- Working in confined spaces

- Road and driving safety

- Attention to detail

- Checklists

- Customer service

- Morale and teamwork

- Conflict resolution

- Health and wellness

For more information and examples, download our white paper: Drive Change and Improve Safety with Digital Signage for Manufacturing Facilities